Education and Research

Hardware Buyers Guide

Are you an Educator or Researcher who needs help deciding which kit or manipulator to purchase? We put together a handy buying guide to answer many frequently ask questions and to guide you through which kits are best for your project goals.

Have More Questions?

We're here to help. Fill out the form and let's chat about your project goals.

TROSSEN AI MISSION

At the core of our Trossen AI hardware line is the ethos of the ALOHA Project—A LOw-cost HArdware—bringing advanced robotics to researchers, students, and engineers at an unparalleled price, making cutting-edge Machine Learning research more accessible than ever.

Keep scrolling to see all the new features we've added ↓

Trossen Data Collection Lab.

Machine Learning Kits.

GUI Touchscreen.

iNerve® Controller.

Driver.

Model Evaluation.

Hugging Face LeRobot.

Data Collection.

Models

-

Transformers

-

Diffusion

-

Etc

Data

-

Parquet

-

HDF5

-

Etc

Moel Training On-Device or in the cloud.

Google CoLab.

DATA COLLECTION THAT JUST WORKS

NO HASSLE SETUP IN 3 SIMPLE STEPS

BECAUSE IT'S MORE THAN JUST HARDWARE

Hardware

Hardware that’s built from the motor up to deliver high performance and longevity.

Next-Gen QDD Servos

A Hybrid-drive design optimized for precision and control.

Robotic Manipulators

Tailor-made for robotic machine learning research.

Workstation Kits

Desktop, tabletop, or mobile; there is a solution for your project needs.

Controllers

Multiphase PID control system allows for the most advanced accuracy, repeatability, and performance.

Lightning-Fast Asynchronous Data Protocol

At over 10,000Hz, it offers a virtually zero-latency operating environment.

Ultra-High Performance iNerve® Controller

Offloads critical computational tasks from your computer, like gravitational compensation, delivering unprecedented responsiveness.

C++ Interbotix UDP Driver

Easily PIP installable with simple Python and ROS bindings for easy and rapid development and integration.

Data Pipelines

Powerful open-source tools and workflows for rapid and collaborative research and development.

Data Collection

Easy-to-use GUI interfaces, cross-compatible data formats, and Hugging Face LeRobot support make data collection a breeze.

Model Training

Simple on-device or cloud-based model training.

Model Evaluation

Fine-tune your models for advanced control and take advantage of pre-trained models for testing.

ITS AN ENTIRE AI PLATFORM

HARDWARE

ONE OF THE MOST COMMON HARDWARE LAYOUTS IN DATASETS

Compatible with a large number of core-model data sets

Aloha | BiACT | OCTO | π0 | Aloha Unleashed | Crossformers | and more!

RUGGED AND BUILT TO LAST

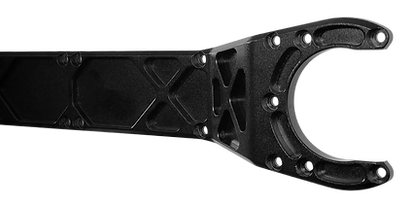

BILLET CNC ALUMINUM

From brackets to idlers, it's built for 10,000s of use cycles

INTEGRATED CABLE MANAGEMENT

With durable reinforced braided data and power cables

NEXT-GENERATION QDD SERVOS

Built for high-torque in a compact lightweight housing

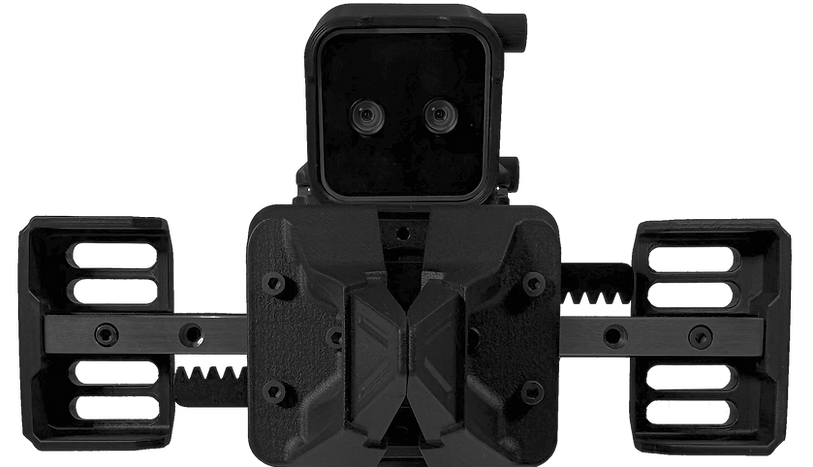

RACK & PINION GEARSET

Providing a linear control in a compact design

JOINT STATE FEEDBACK

Sense interaction forces with built-in servo response

CONTROLLERS

INTERBOTIX DRIVER

OPERATING MODES

-

Position

-

Velocity

-

Torque

-

Gravity Compensation

COMM PROTOCOL

-

UDP over Ethernet

-

Asynchronous

PLATFORMS

-

Linux C++ with Python bindings

-

Easy Python pip installation

-

ROS 2 support

-

URDF/Models for simulators*

-

Native support for Hugging Face LeRobot

500Hz

CONTROL FREQUENCY

ETHERNET

CONNECTIVITY

PIP

EASY INTALLATION

*Support for simulation software will arrive in Q2 2025

iNerve Control Board

CAN FD

HIGH-SPEED PROTOCOL

INDUSTRIAL

HARDWARE GRAV COMP

CUSTOM

PAYLOAD PROFILES

MODEL-BASED CONTROL

Experience unmatched precision and control with advanced compensation for gravity, Coriolis forces, centrifugal forces, and friction—seamlessly calibrated and modeled through servo feedforward torque optimization and eliminating nonlinear components of manipulator dynamics.

HIGH-SPEED CAN FD CONTROL PROTOCOL

CAN FD delivers over 500Hz data transfers, reduced latency, and enhanced real-time performance, enabling seamless communication and superior precision.

CUSTOMIZABLE NETWORK CONFIGURATIONS

Tailor for your network needs—customize IP/DHCP settings, DNS, netmask, and gateway directly on the iNerve Control Board for seamless integration into any network.

CUSTOM LOAD MASS PROFILES

Tailored Precision for Every Payload: The iNerve Control Board empowers researchers to define custom load mass profiles, seamlessly adapting to unique end-effectors and mass-altering additions. Achieve unparalleled gravity compensation for diverse research objectives and project needs.

SERVO CONTROL

PID

CONTROL SCHEMA

QDD

TORQUE SENSING

ADVANCED

SAFETY FEATURES

CASCADING PID CONTROL LOOP

Servo performance is optimized by separately tuning position, velocity, and torque control, ensuring precise movements and minimized overshoot. Advanced error correction increases stability in complex tasks.

ADAPTIVE BANDWITH CONTROL & LOAD BALANCING

Tailored for real-world precision by dynamically optimizing control loops: 1kHz for precise positioning, 4kHz for smooth velocity adjustments, and a blazing 16kHz for torque feedback, ensuring stability and responsiveness during high-demand tasks like dynamic motion and delicate manipulations. Featuring a high-bandwidth linear controller for resource-constrained motors and low-bandwidth model-based feedforward terms for advanced arm control, it delivers unparalleled performance across a range of applications. Additionally, proportional, derivative, and integral gains are fully configurable for each loop, giving researchers and engineers precise control to fine-tune performance for any task.

ADVANCED SAFETY FEATURES

At the forefront of robotic safety, our system is designed with robust features that prioritize user and device protection during operation. From preventing unintended movements to providing enhanced collision awareness, every element is engineered to ensure seamless and safe functionality, whether conducting research or deploying in high-stakes environments. With real-time monitoring, automatic fail-safes, and compatibility checks, our safety protocols instill confidence in every user interaction.

Current Safety Features

-

Joint Constraint Enforcement: Limits on position, velocity, and torque are applied to prevent exceeding safe operational thresholds, regardless of the mode in use.

-

Idle Mode: Implements gravity compensation and significant damping while retaining constrained gripping force, ensuring controlled and secure resting states.

-

Motor Failure Protection: Automatically transitions to idle mode upon motor failure detection, preventing unsafe operations.

-

External Torque Estimation: Enables applications like haptic feedback and collision detection, providing enhanced operational awareness.

-

Handshake Verification: Confirms the integrity of communication between the driver and arm to ensure the correct device is being controlled.

-

Firmware Compatibility Validation: Verifies driver and controller firmware versions align before operation, preventing compatibility issues.

-

System Health Monitoring: Performs checks on all arm components to ensure functionality before allowing user control.

Upcoming Safety Features (Q2 2025)

-

Enhanced Collision Detection: Automatically transitions to idle mode upon detecting collisions, ensuring immediate safety.

-

Communication Quality Monitoring: Activates idle mode in the event of a lossy or unstable connection, maintaining operational integrity.

-

Pre-trajectory Collision Avoidance: Conducts self-collision checks before executing trajectories, safeguarding the system during complex movements.

With these advanced safety features, our system sets a new standard for robotic manipulators, ensuring precision, reliability, and confidence in every application.

MuJoCo

DATA PIPELINES

TOUCHSCREEN GUI

Simple YAML file configuration and your effortlessly collecting data. All bundled kits come with a touchscreen.

DATA FORMATS

Built-in support for common data formats: Parquet, Arrow, and HDF5. Easily utilize your own data format for even more flexibility.

HUGGING FACE LEROBOT

Native support for Hugging Face LeRobot. Data collection pipeline,

data and model storage, and social sharing... All for FREE!

INTERBOTIX PIPELINE

Interbotix combines high-performance C++ with simple Python bindings, offering low-level control and integration with ROS's powerful tools and ecosystem.

ON-DEVICE MODEL TRAINING

Utilize NVIDIA or Intel-based GPUs to train your models.

COLAB CLOUD MODEL TRAINING

With our free Jupyter Notebook template, you can quickly and affordably offload model training to the cloud using Google Colab.

MODEL EVALUATION

Use your own trained models, or shared pre-trained models

to evaluate your model perameters and training settings

HYPERPARAMETERS

Tweak hyperparameters for better results with a single YAML file containing all the settings like the Temporal Ensemble Coefficient, Feed Forward Dimensions, Layers, Heads, ResNet, and many more.

RESOURCES

From startup guides to expert support, explore the tools, documentation,

and protection that come standard with every Trossen Robotics product.

THE TROSSEN PROMISE

We stand behind our products with an industry-leading commitment to reliability, service,

and long-term support—because we believe performance should be measured in years, not months.

BUILT FOR REAL-WORLD RESEARCH ENVIRONMENTS. COVERS DEFECTS IN MATERIALS AND WORKMANSHIP. WEAR COMPONENTS ARE FIELD-REPLACEABLE AND READILY AVAILABLE.

LIFETIME SUPPORT FOR TROSSEN PRODUCTS

COMPARE AI KITS

Solo AI is designed for data collection in the field and for those NOT needing bimanual manipulation.

FAQs

2x Solo AIs CANNOT be converted into a Stationary AI, as we do not sell the frame, cables, and accessories individually.

Stationary AI is designed for those who require bimanual manipulation and a well-controlled lab environment where variables like arm and camera placement are consistent from session to session.

FAQs

Stationary AI can be used as two Solo AIs for data collection in the field.

Stationary AI does NOT come with the table due to the high shipping cost. We recommend a desk with a minimum width of 48" and a minimum depth of 30". The choice of table, including its color, texture, and stability, can have an impact depending on your final use case. Many of our customers aim to implement or fine-tune models like Pi0, Groot, SmolVLA, or Gemini. These models were typically trained on datasets that used a maple-colored tabletop, which is why we recommend the Uline Industrial Packing Table with a maple top.

Here are some key reasons for this recommendation:

-

Visual consistency: Using a similar table helps reduce the domain gap when fine-tuning models trained on standard datasets.

-

Textured surface: The subtle features on the maple surface improve spatial understanding for the model.

-

Color contrast: Light wood tones contrast well with most everyday objects, improving object detection and segmentation.

-

Non-reflective finish: The matte texture minimizes glare and light reflections, leading to cleaner image data.

-

Stability: The table is sturdy, reducing vibrations during demonstrations or evaluation.

Any table with a similar size (approximately 48 inches by 30 inches) and a matte, light wood finish such as maple should work fine. We've observed that using bright or medium-toned wooden surfaces (like maple) helps reduce uncertainty during training by providing good visual contrast and stable surface features. However, other colors, such as black or white, can also be used—as long as you’re aware that you may need to collect more demonstrations and perform additional tuning to achieve comparable results.

If you plan to train models from scratch or operate in a different visual domain, the table color becomes less critical. In that case, collecting more diverse demonstrations can help account for variations in the environment.

Mobile AI is designed for those who require bimanual manipulation in the field, where variables like arm and camera placement are consistent from session to session.

FAQs

Mobile AI can be used as two Solo AIs for data collection in the field.